Eugene's diverse industrial landscape demands skilled industrial electrical experts to meet unique sector needs, from manufacturing to high-tech. These professionals ensure reliable operations through tailored maintenance strategies, including inspections, predictive maintenance, and advanced technology integration. They handle tasks from routine maintenance to system overhauls, optimizing performance, minimizing downtime, and enhancing safety across various industries, ultimately contributing to the sector's efficiency and success. Regular maintenance by these experts prevents costly failures, enhances productivity, reduces risks, and demonstrates the positive outcomes of proactive electrical programs in competitive Eugene markets.

In the heart of Eugene, Oregon’s thriving industrial sector relies on reliable and efficient electrical systems. Understanding the unique challenges these industries face is key to ensuring productivity and safety. This article explores the critical role played by industrial electrical experts in navigating complex electrical needs. From identifying potential hazards to implementing proactive maintenance strategies, their expertise is a driving force behind successful operations. Discover how regular servicing benefits Eugene’s diverse industries and explore real-world examples of transformed businesses through expert industrial electrical solutions.

- Understanding Industrial Electrical Needs in Eugene

- The Role of an Expert: Unlocking Efficient Maintenance

- Key Services Offered by Industrial Electrical Experts

- Benefits of Regular Maintenance for Eugene Industries

- Case Studies: Success Stories from Local Industries

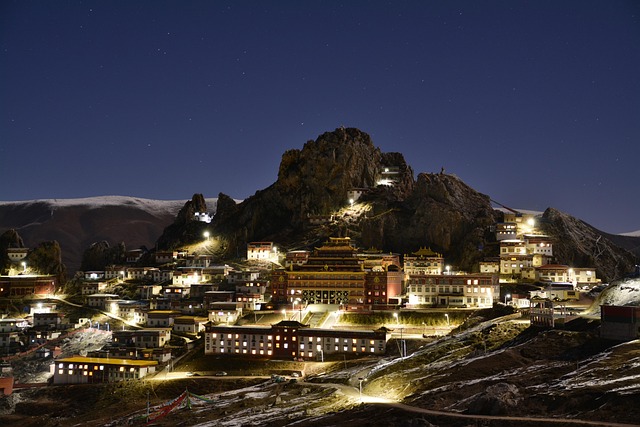

Understanding Industrial Electrical Needs in Eugene

Eugene, with its thriving industrial sector, presents unique challenges and specific requirements when it comes to electrical maintenance. The city’s diverse range of industries, from manufacturing to high-tech, demands a skilled and knowledgeable industrial electrical expert to keep operations running smoothly. Each business has distinct needs, ranging from power distribution and lighting solutions to complex control systems and automation.

Understanding these varied demands is key. Industrial electrical experts in Eugene must be adept at assessing and addressing issues across multiple sectors. They play a vital role in ensuring the reliability and efficiency of industrial operations by implementing tailored electrical maintenance strategies. This includes regular inspections, predictive maintenance, and the integration of advanced technologies to optimize performance and minimize downtime.

The Role of an Expert: Unlocking Efficient Maintenance

In the competitive world of Eugene industries, efficient electrical maintenance is not just a luxury but a necessity. This is where an industrial electrical expert plays a pivotal role. Their expertise lies in understanding the intricate web of electrical systems that power our factories, plants, and other industrial facilities. By leveraging their deep knowledge and skills, they can identify potential issues before they escalate, minimizing downtime and maximizing productivity.

An industrial electrical expert brings a unique set of capabilities to the table, including advanced troubleshooting techniques, up-to-date industry knowledge, and a keen eye for safety. They are equipped to handle a wide range of tasks, from routine maintenance checks to complex system overhauls. Their presence ensures that electrical systems operate at optimal levels, contributing significantly to the overall efficiency and success of Eugene’s industrial sector.

Key Services Offered by Industrial Electrical Experts

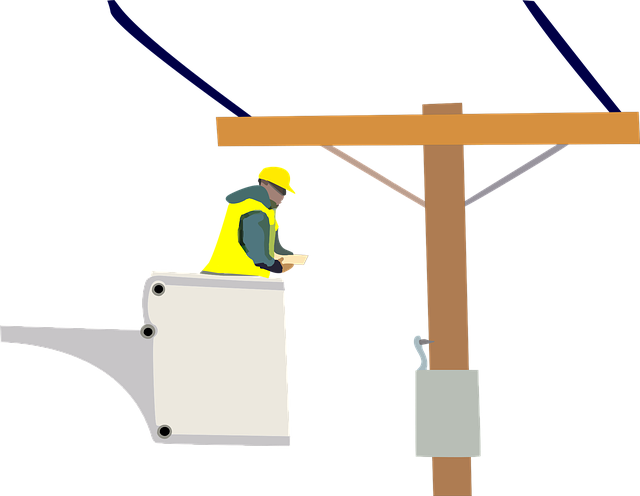

Industrial electrical experts provide a range of essential services tailored to meet the unique needs of various industries in Eugene. Their key offerings include comprehensive electrical installations, designed to ensure safety and efficiency for manufacturing plants, factories, and industrial facilities. These professionals are well-versed in high-voltage systems, complex wiring configurations, and advanced control systems, enabling them to install and maintain critical infrastructure that keeps operations running smoothly.

Moreover, these experts specialize in electrical repairs and maintenance, offering prompt response times to minimize downtime. They conduct thorough inspections, diagnose issues, and implement effective solutions, ranging from minor troubleshooting to major system overhauls. Their expertise includes motor control, lighting systems, back-up generators, and automation technologies, ensuring industrial operations adhere to safety standards and environmental regulations.

Benefits of Regular Maintenance for Eugene Industries

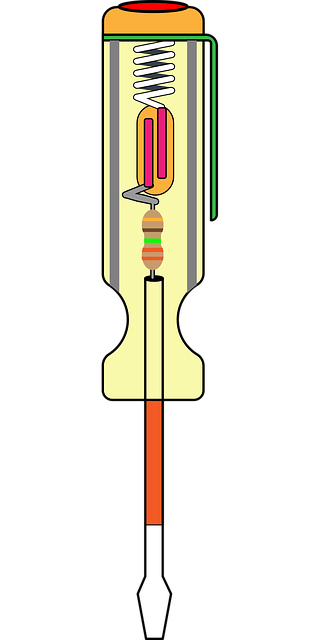

Regular maintenance is a cornerstone for ensuring the smooth operation and longevity of Eugene Industries’ electrical systems. By scheduling routine inspections and proactive repairs, industrial electrical experts can identify potential issues before they escalate into costly failures. This prevents down time, which translates to increased productivity and efficiency for the industry sector.

Well-maintained electrical infrastructure also reduces the risk of hazardous situations such as fires or electrocution. Industrial electrical experts can spot frayed wires, faulty connections, or outdated components that pose a safety threat and address them promptly. This not only safeguards workers but also minimizes financial losses associated with damage to property or equipment due to electrical malfunctions.

Case Studies: Success Stories from Local Industries

In the competitive Eugene industry landscape, efficient electrical maintenance is not just a best practice—it’s a necessity. Local industries have been quick to recognize this, turning to industrial electrical experts for solutions that enhance productivity and safety. Case studies from these forward-thinking companies demonstrate remarkable results, showcasing how strategic electrical maintenance programs can reduce downtime, increase equipment lifespan, and significantly lower operational costs.

One local manufacturing giant, known for its innovative products, implemented a proactive electrical maintenance strategy with the help of an industrial electrical expert. This approach involved regular inspections, predictive analytics, and targeted upgrades, leading to a 30% reduction in unexpected shutdowns over two years. Similarly, a food processing facility adopted a similar strategy, resulting in improved product quality, increased production efficiency, and enhanced employee safety. These success stories serve as powerful examples of how industry leaders are leveraging the expertise of industrial electrical specialists to drive operational excellence.